Home / Blog Posts / How to Correctly Size Electrical Conductors

Learn the complete process for selecting the correct size of electrical conductors in compliance with BS 7671 and Ghana Electrical Wiring Regulations 2011 (L.I. 2008). This guide covers temperature limits, voltage drop, fault capacity, installation methods, protective devices, and certification to ensure safe, efficient, and compliant electrical installations.

Choosing the correct size for an electrical conductor during installation is one of the most critical design steps in any electrical project. It directly impacts the safety, performance and reliability of the entire system. An undersized conductor can overheat, cause voltage drop issues, and increase the risk of fire, while an oversized conductor can lead to unnecessary costs and installation difficulties.

According to the IET Wiring Regulations (BS 7671:2018, 18th Edition), conductor sizing must be determined based on expected operating conditions, potential fault scenarios, and regulatory safety requirements. The goal is twofold:

Regulation 132.1(ii) emphasises that conductors, along with their connections, terminations, supports, and enclosures, must be selected and erected with due consideration for the fundamental principles set out in Chapter 13. This means taking into account mechanical strength, temperature ratings, voltage drop, fault currents, and environmental conditions.

In practice, correct conductor sizing involves a multi-step engineering process. Designers must calculate the design current (Ib), select a conductor with an adequate current-carrying capacity (Iz), ensure protective devices operate correctly, and check compliance with maximum voltage drop and fault withstand criteria.

The Ghana Electrical Wiring Regulations 2011 (L.I. 2008) also align with these principles, requiring that all electrical works be designed and executed in a way that ensures safety and efficiency. Regulation 5 specifically mentions that equipment and wiring must be selected and erected in accordance with recognised standards such as BS 7671.

In short, conductor sizing is not guesswork, it is an engineering decision based on scientific calculation, safety margins, and compliance with law. The following sections provide a step-by-step approach to getting it right.

The fundamental principles for conductor sizing, as outlined in BS 7671 Chapter 13 and Section 132, revolve around ensuring both protection and functionality. This involves considering the following key aspects:

BS 7671 Regulation 131.1 specifies that every installation must be designed to prevent dangerous thermal effects in conductors under both normal operation and fault conditions. Conductors should not be subjected to temperatures that could degrade insulation or compromise mechanical integrity.

For example, copper conductors in thermoplastic insulation typically have a maximum permissible operating temperature of 70°C. If conductors run hotter than this for prolonged periods, insulation breakdown can occur, leading to short-circuits or fire.

Another fundamental consideration is fault current withstand capability. Conductors must be able to sustain the thermal and electromechanical stresses during short-circuits until protective devices operate. This is why Regulation 132.6 requires calculations for both normal operating conditions and foreseeable fault conditions.

The Ghana Electrical Wiring Regulations reinforce this in Regulation 3, stating that installations must be designed and constructed so as to ensure safety from hazards, with particular attention to the integrity of conductors and connections.

In real-world terms, this means that before selecting a conductor size, the designer must assess:

Skipping these considerations can lead to unsafe or non-compliant installations — something both BS 7671 and Ghanaian law strictly prohibit.

The admissible maximum temperature is a crucial limit in conductor sizing because it defines the maximum safe operating temperature that a conductor and its insulation can sustain without damage.

BS 7671 Appendix 4 specifies these temperature limits:

The temperature limit applies to continuous operation under design load. If the load or environmental factors push the conductor above this limit, insulation breakdown can occur, increasing the risk of faults and fire.

Temperature limits are also important at connection points. BS 7671 Regulation 512.1.5 warns that if a conductor operates above 70°C, any connected equipment (e.g., switchgear, terminals) must be rated for the resulting temperature rise at the connection point.

The Ghana Electrical Wiring Regulations, while not specifying exact temperature numbers, require that materials and equipment be suitable for the maximum temperatures they are likely to experience in service. This means that during the design phase, engineers must calculate conductor operating temperatures based on current-carrying capacity, ambient temperature, and installation method.

For example:

If a 6 mm² PVC copper cable runs in conduit inside a wall with an ambient temperature of 40°C, the tabulated current-carrying capacity must be reduced using the ambient temperature rating factor from BS 7671 Table 4B1. This ensures that even under worst-case conditions, the conductor temperature will remain within safe limits.

By observing admissible maximum temperatures, we safeguard both the longevity and safety of the electrical installation.

Voltage drop is a natural phenomenon in electrical circuits, caused by the resistance and reactance of conductors. If excessive, it can lead to poor equipment performance, overheating, and energy waste.

BS 7671 Regulation 525.1 sets maximum voltage drop limits for installations supplied directly from a public low-voltage distribution system:

For private low-voltage supplies, the limits increase to 6% (lighting) and 8% (other uses), but final circuits must still adhere to the public supply limits.

Voltage drop (Vd) is calculated using the formula:

Vd = mV/A/m × Ib × L ÷ 1000

Where:

It is important to include harmonic effects in voltage drop calculations, especially for circuits serving non-linear loads like LED lighting, variable speed drives, or IT equipment.

The Ghana Electrical Wiring Regulations indirectly address this by requiring installations to be designed for efficient operation, which includes ensuring supply voltage remains within equipment tolerance limits.

Practical example:

A 32 A ring final circuit supplying socket outlets over a 40 m run may require upgrading from 2.5 mm² to 4 mm² conductors if the calculated voltage drop exceeds 5%, especially under continuous load.

Ignoring voltage drop calculations can result in dim lighting, motor stalling, and premature failure of sensitive electronics, all of which can be avoided by correct conductor sizing.

Conductors must be able to withstand the thermal and mechanical forces produced by fault currents until protective devices operate. This is known as short-circuit withstand capacity.

BS 7671 Regulation 434.5.2 provides the adiabatic equation for calculating the minimum conductor cross-section for fault protection:

S = √(I² × t) ÷ k

Where:

For example, a copper conductor with PVC insulation has a k value of 115. If a fault current of 5,000 A flows for 0.4 seconds before disconnection, the minimum CSA is:

S = √(5000² × 0.4) ÷ 115 ≈ 6.16 mm²

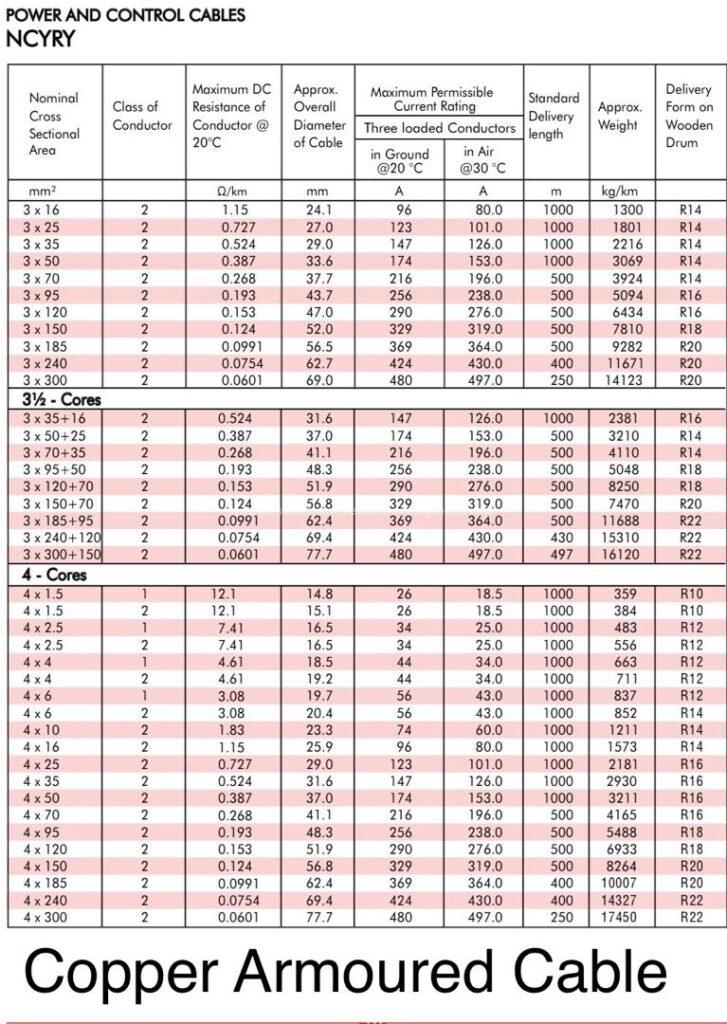

Mechanical stresses are another consideration. Cables may be subjected to tension, bending, vibration, or compression during installation and service. BS 7671 requires that cables be installed to avoid undue mechanical strain, and in some cases, protective coverings or armour are necessary.

The Ghana Electrical Wiring Regulations support this by requiring wiring systems to be mechanically protected where there is a risk of damage — for example, using steel wire armoured (SWA) cable for underground runs.

Failing to consider short-circuit and mechanical stresses can lead to catastrophic failure, including conductor breakage, insulation rupture, and fire hazards.

While electrical performance is the primary focus in conductor sizing, mechanical strength is equally important. Conductors may face physical stress during installation and throughout their service life. BS 7671 Regulation 522.6 highlights that wiring systems must be selected and erected to withstand impact, abrasion, tension, compression, and bending without sustaining damage.

Mechanical stresses can arise from:

Where cables are installed underground or in walls, additional protection is often needed. For example:

The Ghana Electrical Wiring Regulations echo these requirements in Regulation 5 by stating that wiring systems must be “so selected and erected as to avoid damage arising from mechanical stress in normal service.” This means a designer must consider not only the conductor size for electrical reasons but also whether its mechanical properties are sufficient for the installation method chosen.

Practical example: A 1.5 mm² cable may meet electrical requirements for a lighting circuit, but if it is installed in an industrial workshop where it could be snagged or crushed, a physically stronger cable or additional protective conduit might be necessary.

Correct conductor sizing is also essential for ensuring the operation of protective devices in fault conditions. If the impedance of a circuit is too high, the fault current may be insufficient to trip or blow the protective device within the required disconnection time, leaving the system unsafe.

BS 7671 Regulation 411.4.4 requires that for TN systems, the earth fault loop impedance (Zs) must be low enough to allow automatic disconnection within:

The maximum permissible Zs values are listed in BS 7671 Tables 41.2 to 41.4 for various types of protective devices.

The formula for verifying compliance is:

Zs ≤ Uo / Ia

Where:

In Ghana, the Electrical Wiring Regulations require installations to be tested to confirm earth fault loop impedance values before they are energised.

For example: If a circuit breaker is rated at 20 A and requires 100 A to trip within 0.4 seconds, then the maximum permissible Zs is:

Zs = 230 / 100 = 2.3 Ω

If the measured Zs is higher than this, either a larger conductor or a different protective device must be selected.

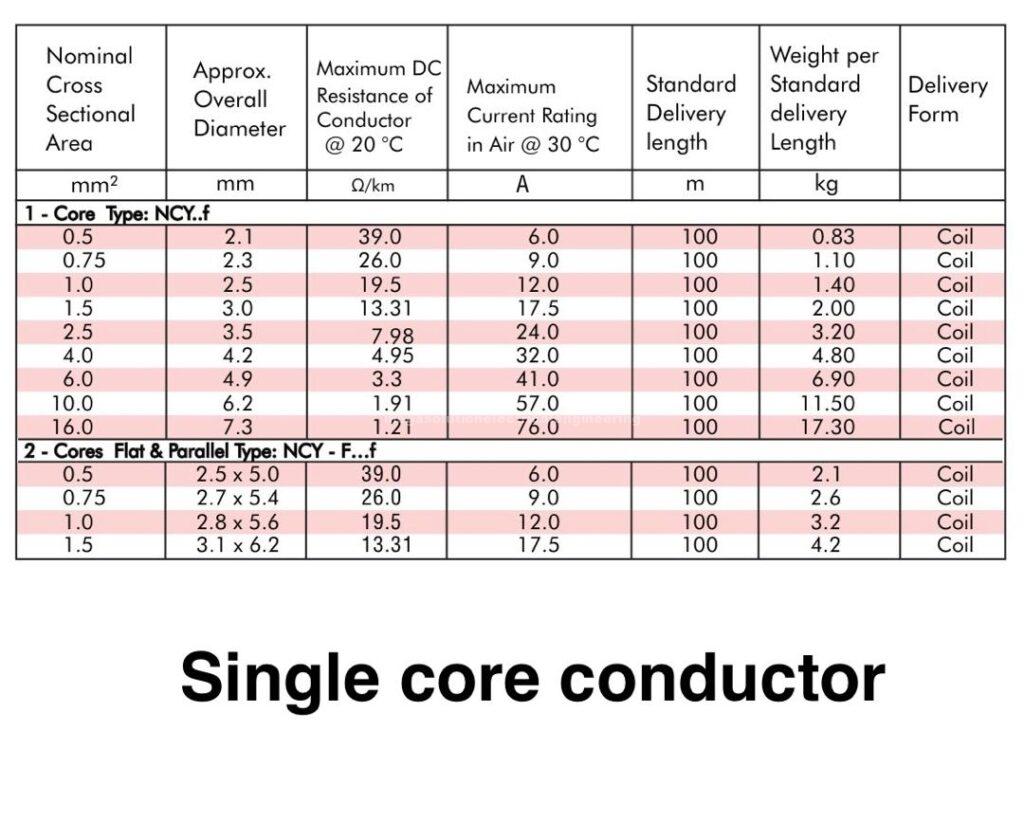

The installation method has a major impact on the current-carrying capacity of a conductor. BS 7671 Appendix 4 provides current ratings for different installation reference methods, such as:

Method C: Clipped direct to a surface.

Method B: Enclosed in conduit in thermally insulating wall.

Method D: Direct in ground or duct.

Method E: In free air.

The same conductor size can carry significantly different currents depending on the method. For example, a 4 mm² PVC copper cable clipped direct (Method C) may carry around 37 A, but enclosed in insulation (Method 102) may be limited to around 27 A.

Factors affecting installation method choice include:

Nature of location (domestic, commercial, industrial).

Nature of supporting structure (steel trunking, timber joists, buried in ground).

Accessibility to persons or livestock.

External influences such as moisture, chemicals, or mechanical impact.

The Ghana Electrical Wiring Regulations require that installation methods match environmental and mechanical conditions, making BS 7671’s reference method tables essential for compliance.

Failing to adjust for installation method can lead to serious overheating and premature cable failure.

In circuits serving non-linear loads such as LED lighting, IT servers, and variable speed drives, harmonic currents can be significant. BS 7671 Regulation 524.2.1 warns that in three-phase systems, the neutral conductor may be a fully loaded conductor if the total harmonic distortion (THD) of the third harmonic and its multiples exceeds 15% of the fundamental.

This is because third harmonic currents in each phase are in phase with each other in the neutral, so they add instead of cancelling. In extreme cases, the neutral current can exceed the phase current.

For example, in a three-phase office lighting circuit with high electronic ballast content, a 25 mm² phase conductor may require a 35 mm² neutral to prevent overheating.

BS 7671 also notes that for large conductors, skin effect and proximity effect at higher frequencies increase resistance, reducing current-carrying capacity.

In Ghana, Regulation 5 of the Electrical Wiring Regulations specifies that equipment and wiring must be compatible with the load, which includes harmonic effects. This means harmonic assessment should be part of conductor sizing for modern installations.

Thermal insulation can dramatically reduce the current-carrying capacity of cables by preventing heat dissipation. BS 7671 Regulation 523.9 warns against installing cables completely surrounded by insulation unless their rating has been corrected using the factors in Table 4C1.

For example, if a cable is totally surrounded by thermal insulation for 0.5 m or more, its capacity may need to be reduced to 50% of the value for the same cable clipped direct. Even shorter lengths require appropriate derating.

In practice:

Ghana’s wiring regulations do not give specific derating figures but require compliance with internationally recognised standards, making BS 7671’s tables applicable.

Thermal effects are particularly important in lofts, wall cavities, and retrofitted insulation upgrades, where previously adequate cable sizes can become unsafe after building modifications.

The current-carrying capacity of a conductor, often denoted as Iz, is the maximum current it can carry continuously without its temperature exceeding the limit for its insulation type. BS 7671 Appendix 4 provides tables for standard reference conditions, but in real installations, adjustments are necessary to account for environmental and installation factors.

These adjustments are made using rating factors, commonly referred to as C-factors:

The formula for determining the required Iz is:

Iz ≥ Ib / (Ca × Cg × Ci × Cs × Cd)

Where Ib is the design current. This ensures the cable is still adequate after all correction factors are applied.

Ghana’s Electrical Wiring Regulations require that cable selection accounts for “anticipated service conditions,” which in practice means applying these C-factor adjustments exactly as outlined in BS 7671.

A conductor’s size must also coordinate with the protective device used. BS 7671 Regulation 433.1.1 states:

This ensures that in an overload situation, the device trips before the conductor’s temperature rises to dangerous levels.

For example, if Iz = 27 A, then:

I₂ ≤ 1.45 × 27 = 39.15 A

If the protective device is an MCB with I₂ = 45 A, this would be unsafe unless a larger conductor is chosen.

For fault protection, the protective device must disconnect the circuit before the conductor reaches its maximum thermal limit. This is where short-circuit calculations and the adiabatic equation for protective conductors come into play.

In Ghana, Regulation 3 of the Electrical Wiring Regulations stresses that wiring must ensure the “protection of persons, livestock, and property” from overcurrent hazards, making proper protective device coordination a legal requirement.

Even if calculations suggest a smaller size is adequate, BS 7671 imposes minimum conductor sizes for safety and mechanical robustness. Table 52.3 specifies:

Special cases:

Ghana’s standards also align with these minimums, requiring that conductors be large enough to withstand both electrical load and mechanical handling during installation and service.

BS 7671 generally requires the neutral conductor to be the same size as the phase conductor up to 16 mm² copper (25 mm² aluminium).

Exceptions allow reduced neutral sizes for larger conductors, provided:

However, in systems with significant harmonic content (common in offices, data centres, and industrial facilities), the neutral may actually need to be larger than the phase conductor.

Ghana’s Electrical Wiring Regulations adopt the same principle, stating that conductors must be “adequate for the load they are intended to carry,” which includes harmonic-induced neutral currents.

Main protective bonding ensures all exposed conductive parts and extraneous conductive parts are at the same potential, reducing the risk of electric shock.

BS 7671 Table 54.8 specifies bonding conductor sizes relative to the supply PEN conductor:

Bonding conductors may be smaller if mechanically protected, but never below the statutory minimums.

In Ghana, bonding is mandatory for metallic water pipes, gas pipes, structural steel, and other conductive building parts, and its sizing must be in accordance with these international standards.

Both BS 7671 and Ghana’s Electrical Wiring Regulations stress that proper documentation is not optional. Every electrical installation must be accompanied by clear records detailing:

Under BS 7671, this is part of the Electrical Installation Certificate (EIC) process. It ensures that future inspections, maintenance, and modifications are carried out with full knowledge of the existing system.

In Ghana, Regulation 5 of the Electrical Wiring Regulations requires adherence to approved standards, and Regulation 3 requires safety and functionality be documented. The Energy Commission also mandates that installations be tested and certified by licensed professionals before energisation. This formal process ensures that conductor sizing, installation methods, and protective measures are traceable and verifiable.

Choosing the correct conductor size involves more than matching a cable to a breaker. The process should follow these steps:

This systematic approach ensures compliance with both BS 7671 and Ghana’s LI 2008 while safeguarding against fire, shock, and premature equipment failure.

Correct conductor sizing is the backbone of a safe and efficient electrical installation. By following BS 7671’s detailed requirements and Ghana’s Electrical Wiring Regulations, installers can ensure that systems operate within safe temperature limits, maintain voltage quality, withstand fault conditions, and comply with legal safety obligations.

A well-sized conductor is more than just copper or aluminium, it is an investment in safety, performance, and long-term reliability. Inadequate sizing may save money in the short term but risks costly failures, dangerous overheating, and legal non-compliance.

Electrical design is as much about prevention as it is about performance. With careful calculation, proper application of correction factors, and meticulous documentation, every installation can meet the highest standards of safety and functionality.

Trustindex verifies that the original source of the review is Google. I hired a licensed electrician from mega solution electrical in Kumasi, the service was done professionally and met all standards. It gave me peace of mind. I will recommend them to every bodyPosted onTrustindex verifies that the original source of the review is Google. They’re the best and most reliable electrical company in Ghana I’ll always recommend them to everyonePosted onTrustindex verifies that the original source of the review is Google. Thanks for solving our electrical problem so fast, coming all the way to Cantonments.Posted onTrustindex verifies that the original source of the review is Google. Mega Solution demonstrates exceptional expertise in genset systems. Their professionalism, technical proficiency, and industry experience set them apart. I highly recommend their services to anyone seeking reliable and knowledgeable partners in this field.Posted onTrustindex verifies that the original source of the review is Google. This best experience I had in a while, Richard provided all the help I was looking for. Thank you, this is a 10 Stars service!Posted onTrustindex verifies that the original source of the review is Google. Best electrical company in GhanaPosted onTrustindex verifies that the original source of the review is Google. Best Electrician in Ghana | best electrical engineer at good location | over 30 years experience | good electrical service. Thank you so much. I’m very happyPosted onTrustindex verifies that the original source of the review is Google. Wonderful work you have to try

When searching for a reliable electrician, call us at +233 24 415 1232 We specialize in electrical repairs, indoor and outdoor lighting installations, panel upgrades, and even hot tub wiring!

No matter urgent any electrical repairs seem, it’s never okay to attempt to handle them on your own. Trying to take care of electrical problems without professional training is extremely dangerous. If you or someone else aren’t hurt during your attempt, there’s still a chance that you’ve left something undone that poses a huge risk to you, your home, or your family.

mega solution electrical Power and wiring audit in Accra, Ghana knows what a hassle any electrical problems can be, which is why we’ll always respond to any requests for service as quickly as possible. And because all of our technicians are licensed, background checked, and professionally trained, you’re guaranteed to receive the best quality service and workmanship available when you call us. We can assist with all your electric needs including:

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |||

| 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| 26 | 27 | 28 | 29 | 30 | 31 | |

Learn how to read and understand circuit breaker ratings like In, Icu,

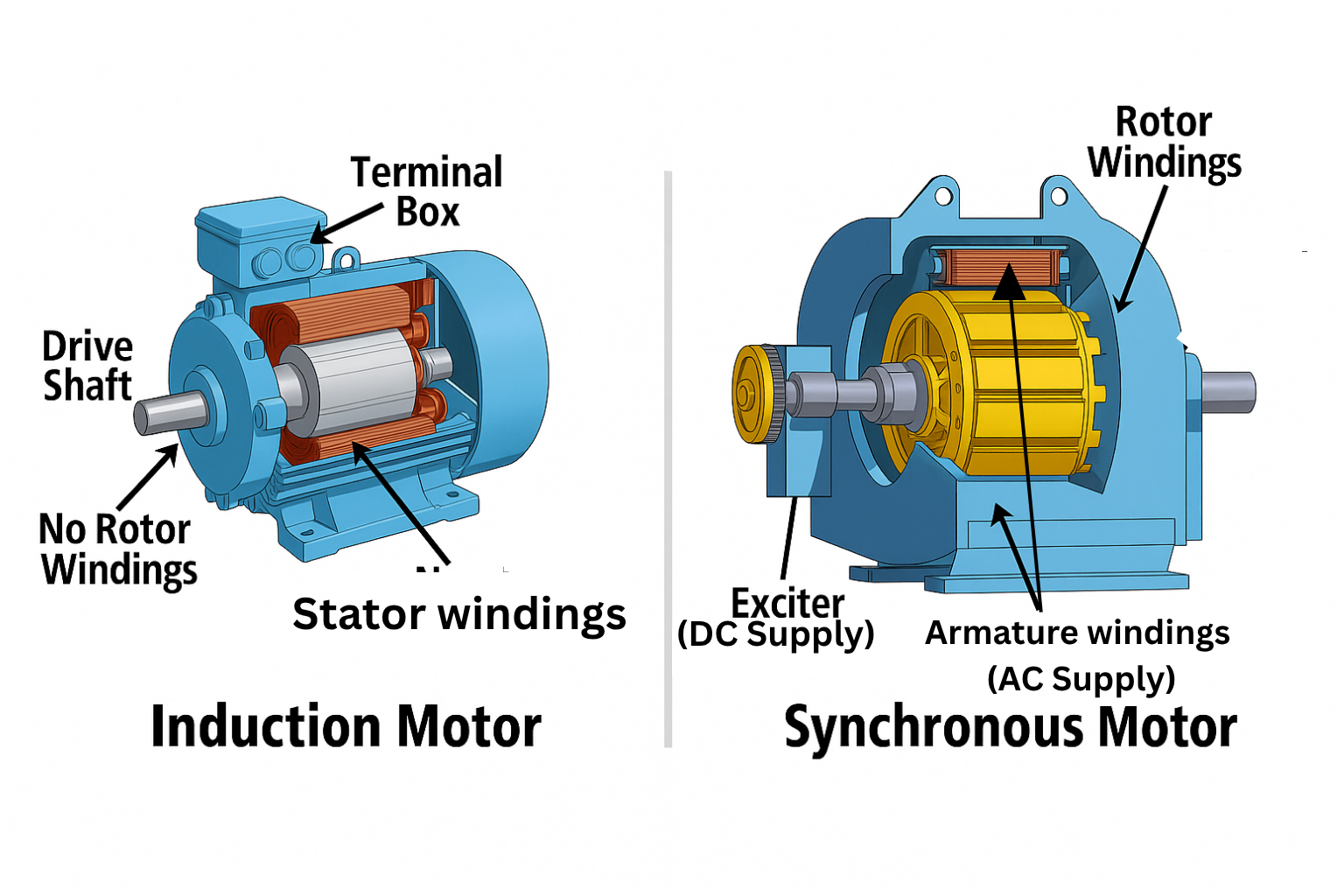

Discover the key differences between synchronous and induction motors.

What safety measures you need to put in place in your industry and why

As energy bills continue to soar, households and businesses alike are

Dreaming of a Career as an Electrician in Ghana? Here's How to Make It

Characteristics of Top Electricians Before starting your search, it's