Home / Blog Posts / Synchronous Motors vs Induction Motors

Synchronous Motors vs Induction Motors

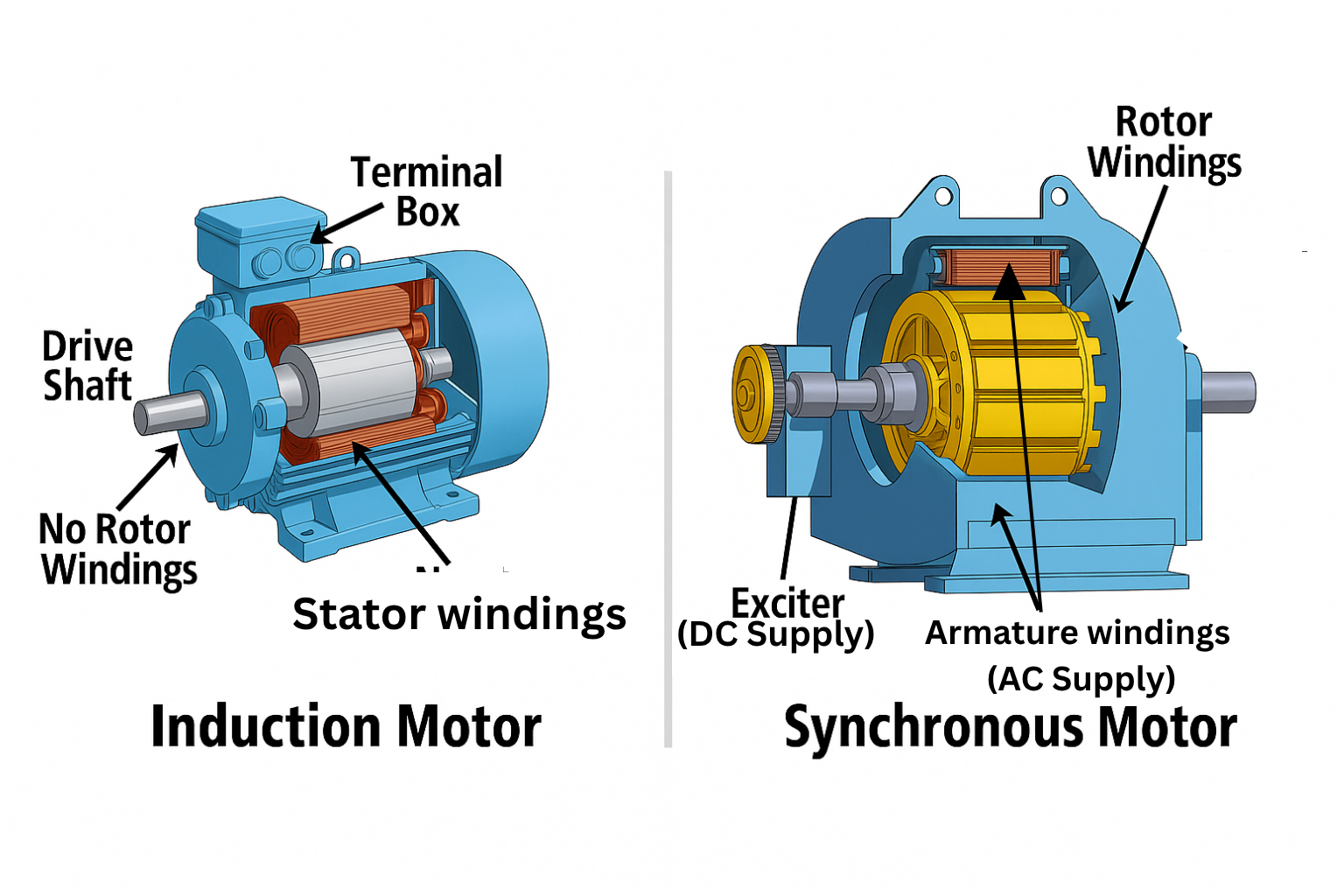

In electrical engineering, AC motors are classified into two main types: Synchronous Motors and Induction Motors. Though both rely on a rotating magnetic field produced by a three-phase stator, the way they function internally is quite different. Understanding their construction, behaviour, and performance is key for selecting the right motor in industrial, commercial, or residential applications.

A Comprehensive Comparison of Two Essential Types of Electric Motors

In the world of electric motors, two types stand out for their unique characteristics and applications: Synchronous Motors and Induction Motors. While both are used to convert electrical energy into mechanical energy, they differ significantly in their design, functionality, and usage. In this article, we’ll delve into the differences between Synchronous Motors and Induction Motors, helping you understand which one is best suited for your specific needs.

Synchronous Motors: Precision and Efficiency

Synchronous Motors are a type of AC motor that operates at synchronous speed — meaning the rotor rotates in exact synchrony with the rotating magnetic field of the stator. This constant speed makes synchronous motors ideal for applications requiring precision, high efficiency, and power factor correction.

Key Construction Features:

Stator Windings (Armature Windings)

Just like in induction motors, the stator is wound with 3-phase AC coils. These create the rotating magnetic field that drives the motor. Importantly, in most synchronous motors, the stator is also referred to as the armature because it’s where the main AC power interacts.Rotor Windings (Field Windings)

The rotor contains DC-excited windings, supplied either through slip rings or a brushless exciter. These windings generate a steady magnetic field that locks onto the stator’s rotating field, ensuring the rotor rotates at the same speed as the stator field.Exciter (Auxiliary DC Source)

A small auxiliary generator called an exciter provides the DC power to the rotor windings. Some modern motors use brushless excitation systems, improving efficiency and reducing maintenance.

Clarification:

The armature winding is often misunderstood to be on the rotor. In synchronous motors used as motors (not generators), the armature (AC winding) is on the stator, while the rotor carries the DC field winding.

Induction Motors: Robustness and Versatility

Induction Motors, on the other hand, are the most widely used type of AC motor. They work on the principle of electromagnetic induction, where the stator’s magnetic field induces a current in the rotor, causing it to rotate. Induction Motors are known for their ruggedness, simplicity, and low maintenance costs. They are available in a range of designs, including squirrel-cage and wound-rotor types, making them suitable for various applications.

What Happens when a DC and AC supply is applied to synchronous motor

When the Rotor Takes DC Supply (in a Synchronous Motor):

When DC power is supplied to the rotor windings, it creates a steady magnetic field (north and south poles) on the rotor. This magnetic field does not rotate on its own but becomes a fixed magnetic source. When the motor is started and brought close to synchronous speed (typically using an external motor starter or damper winding), this DC-excited rotor locks into synchronism with the rotating magnetic field produced by the stator. From that point on, the rotor and stator field rotate together at the same speed, enabling stable and constant-speed operation.

When the Stator Takes AC Supply (in a Synchronous Motor):

Supplying 3-phase AC power to the stator windings generates a rotating magnetic field at synchronous speed. This rotating field sweeps around the stator and creates a rotating magnetic flux. This flux interacts with the DC-excited magnetic field on the rotor. Once synchronism is achieved, the rotor is “pulled” along by the rotating stator field and continues turning at exactly the same speed — this is why the motor is called “synchronous.”

What Happens When AC Supply is Fed to an Induction Motor:

When three-phase AC supply is fed to the stator windings of an induction motor, it produces a rotating magnetic field that sweeps around the stator at a speed called synchronous speed. This changing magnetic field cuts across the rotor conductors, which are usually short-circuited bars (in squirrel cage motors).

According to Faraday’s Law of Electromagnetic Induction, this motion induces a current in the rotor conductors. The induced current in the rotor then produces its own magnetic field. The interaction between the stator’s rotating magnetic field and the rotor’s induced magnetic field produces a torque that causes the rotor to turn.

However, the rotor can never reach synchronous speed because there must be relative motion between the stator field and the rotor for induction to occur. This small difference in speed is called “slip.” The rotor typically rotates at about 95–98% of the synchronous speed, depending on load conditions.

Key Construction Features:

Stator Windings

Like synchronous motors, induction motors also use a 3-phase stator winding to generate a rotating magnetic field.Rotor (No Windings in Squirrel Cage Type)

Most induction motors use a squirrel cage rotor. This rotor has conductive bars (usually aluminium or copper) short-circuited by end rings — no coil windings or electrical connections are required on the rotor.Induced Current

The rotating field of the stator induces current in the rotor bars. This current interacts with the magnetic field, generating torque and causing the rotor to turn. The rotor speed always lags behind the stator field, hence the term “asynchronous.”

Key Differences Between Synchronous and Induction Motors

| Feature | Synchronous Motor | Induction Motor |

|---|---|---|

| Rotor Speed | Always matches stator field (synchronous) | Slightly less than stator field (slip) |

| Rotor Supply | Requires DC excitation | No separate supply; induced internally |

| Stator Winding | 3-phase AC (armature) | 3-phase AC |

| Power Factor | Can be unity or leading (adjustable) | Always lagging |

| Efficiency | Higher (especially at full load) | Moderate (varies with load) |

| Cost | Generally more expensive | Economical and simpler |

| Speed Control | Very stable | Varies with load unless controlled |

| Applications | Precision tools, compressors, synchronous condensers | Pumps, fans, HVAC systems, conveyors |

Choosing the Right Motor

When deciding between a Synchronous Motor and an Induction Motor, consider the specific requirements of your application. Synchronous Motors are ideal for:

- High-precision applications, such as robotics and CNC machines

- High-power applications, such as industrial drives and generators

- Applications requiring high efficiency and power factor correction

Induction Motors, on the other hand, are suitable for:

- General-purpose applications, such as pumps, fans, and conveyor belts

- Applications where simplicity and ruggedness are essential

- Applications with variable speed requirements

Synchronous Motors and Induction Motors have distinct characteristics that make them suited for different applications. By understanding the differences between these two types of motors, you can make an informed decision when selecting a motor for your specific needs. Whether you require precision, efficiency, or robustness, there’s a motor out there that’s right for you.

Trustindex verifies that the original source of the review is Google. Thank you Mega Solution Electrical Engineering for your prompt and Professional Electrical Service in Tema Sakumono( C.O.P Sophia Cudjoe Temple) We will always get in touch for further contracts. Good Job!Posted onTrustindex verifies that the original source of the review is Google. I hired a licensed electrician from mega solution electrical in Kumasi, the service was done professionally and met all standards. It gave me peace of mind. I will recommend them to every bodyPosted onTrustindex verifies that the original source of the review is Google. They’re the best and most reliable electrical company in Ghana I’ll always recommend them to everyonePosted onTrustindex verifies that the original source of the review is Google. Thanks for solving our electrical problem so fast, coming all the way to Cantonments.Posted onTrustindex verifies that the original source of the review is Google. Mega Solution demonstrates exceptional expertise in genset systems. Their professionalism, technical proficiency, and industry experience set them apart. I highly recommend their services to anyone seeking reliable and knowledgeable partners in this field.Posted onTrustindex verifies that the original source of the review is Google. This best experience I had in a while, Richard provided all the help I was looking for. Thank you, this is a 10 Stars service!Posted onTrustindex verifies that the original source of the review is Google. Best electrical company in GhanaPosted onTrustindex verifies that the original source of the review is Google. Best Electrician in Ghana | best electrical engineer at good location | over 30 years experience | good electrical service. Thank you so much. I’m very happy

When searching for a reliable electrician, call us at +233 24 415 1232 We specialize in electrical repairs, indoor and outdoor lighting installations, panel upgrades, and even hot tub wiring!

Always Hire a Professionals

No matter urgent any electrical repairs seem, it’s never okay to attempt to handle them on your own. Trying to take care of electrical problems without professional training is extremely dangerous. If you or someone else aren’t hurt during your attempt, there’s still a chance that you’ve left something undone that poses a huge risk to you, your home, or your family.

Electric Motor Rewinding in Accra – Ghana

Our electric motor rewinders in Accra, Ghana know what a hassle any electrical problems can be, which is why we’ll always respond to any requests for service as quickly as possible. And because all of our technicians are licensed, background checked, and professionally trained, you’re guaranteed to receive the best quality service and workmanship available when you call us. We can assist with all your electric needs including:

- Generator Installation and Repair Services

- Best Industrial Electrical Automation services

- Best Electric Motor Rewinding Services

- Earthing Installations and Upgrades Services

- Electro-Mechanical services

- Lighting Installation

- Residential Electrical Installation Services

- Electrical Panel Replacement

- LED Lighting

- Industrial electrical Installation Services

- Electrical Troubleshooting and Repairs

- Professional Electrical Support and Training Services

- Electrical Wiring Design and Engineering Services

- Electrical Energy and Power Auditing Services

- Distribution Panels Fabrication and Upgrades Services

- Professional electrical contractors in Ghana

- Commercial electrical Installation Services

- Licensed Electricians in Ghana

- Home Wiring

- Consulting and Advisory services

- Electrical Wirings Testing and Inspection Services

- Wiring Replacement and Upgrade Services

- Residencial, commercial and Industrial wiring Services

Search

Electrical Wiring Contract – What Can Go Wrong or Right

Generator Service Experts in Ghana, When the Lights Go Out – Mega Solution Electrical to the Rescue!

Categories

- Certified Electricians Ghana

- Commercial Electrical Services

- Commercial Installation

- Consulting Services

- Contracting Services

- Control Systems

- Distribution Panel Fabrication

- Earthing Installations

- Earthing Maintenance

- Electrical Consulting

- Electrical Contractors

- Electrical Installation Ghana

- Electrical Maintenance Ghana

- Electrical Repair Ghana

- Electrical Safety

- Electrical Services

- Electrical Training

- Energy Auditing

- Engineering Services

- Generator Installation

- Generator Load Testing

- Generator Repair

- Generator Services

- Generator Servicing Ghana

- Ghana Electrical Licensing

- Ghana Electrical Services

- Industrial Electrical Services

- Industrial Installation

- Industrial Services

- Industrial Solutions

- Installation Services

- Licensed Electricians

- Motor Rewinding

- Residencial Installation

- Residential Electrical Service

- Residential Services

- Uncategorized

Archive

| M | T | W | T | F | S | S |

|---|---|---|---|---|---|---|

| 1 | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| 16 | 17 | 18 | 19 | 20 | 21 | 22 |

| 23 | 24 | 25 | 26 | 27 | 28 | |

Tags

- Commercial Electrical Contracting

- Commercial Electrical Installation Ghana

- Commercial Electrical Repair

- Commercial Electrical Wiring

- Commercial generator maintenance

- Earthing Installations and Upgrades Services

- Electrical

- Electrical Automation Services

- Electrical CAD Design

- Electrical Company

- Electrical Contractors in Ghana

- Electrical Energy and Power Auditing Services

- Electrical Wiring Design and Engineering Services

- Electrical Wiring Design Ghana

- Electrical Wiring Upgrades

- Electricians

- Electricians in Ghana

- Electric Motor Repair

- Electric Motor Rewinding

- Electric Motor Rewinding Services

- Factory Electrical Installation

- Generator experts in Ghana

- Generator installation

- Generator Installation and Repair Services

- Generator Installation Ghana

- Generator Maintenance Contracts

- Generator Repairs

- Generator Repair Services

- Generator Repair Services Ghana

- Generators

- Industrial Electrical Contracting

- Industrial Electrical Installation Ghana

- Industrial Electrical Maintenance

- industrial Electrical Repair

- Industrial Electrical Wiring

- Industrial generator repair services

- Installations

- Licensed Electrical Contractors Ghana

- Licensed Electricians in Ghana

- Residential Electrical Installation Ghana

- Residential Electrical Maintenance

- Residential Electrical Repair

- Residential Electrical Wiring

- Residential standby generator repair

- Wiring Installation Design

Prayer Warfare

Synchronous and induction motors each have unique features that make them ideal for different tasks. Understanding their differences can help you choose the right motor for your project, whether it’s for precise speed control or rugged, variable-speed applications. Which type of motor do you usually work with?

I don’t really get you but we repair all electric induction motors